Regardless of the nature of the business you do, you need pumps if you are moving. However, this requires tremendous energy, but people must look for creative ways to save the cost of energy and money. Water pump installation cost can be quite high, but with the right steps, it can save you a lifetime of bills. Below are some maintenance tips homeowners can use to save energy and cost.

When you understand how water pump works, it becomes easier for you to take the proper measures. You can tell the advantages of power supply and the impact it has on the water pump installation cost. All your efforts must be towards preventing energy loss.

Efficient Pump Management

Proper maintenance of your pumps allows you to keep your facilities running efficiently. Regular maintenance can reveal any deterioration in capacity and efficiency which occurs before the pump fails. There are many different types of power supply. If you are in Australia and New Zealand you must have heard of DEUTZ DRIVE, a low fuel consumption engine that has been designed locally and specifically. The installation company must understand how water pump works beforehand.

Maintenance activities are classified as either being predictive or preventive. Preventive maintenance focuses on conventional system needs e.g. removal of contaminants, adjustment, and lubrication. Predictive addresses the tests and inspections that detect a looming problem.

In some places, this is called condition monitoring or assessment. With modern testing equipment and methods, testing has become a lot easier. With such measures, you can reduce costly unplanned outages. The kind of water pump engine you choose determines the amount of energy and cost you’ll save.

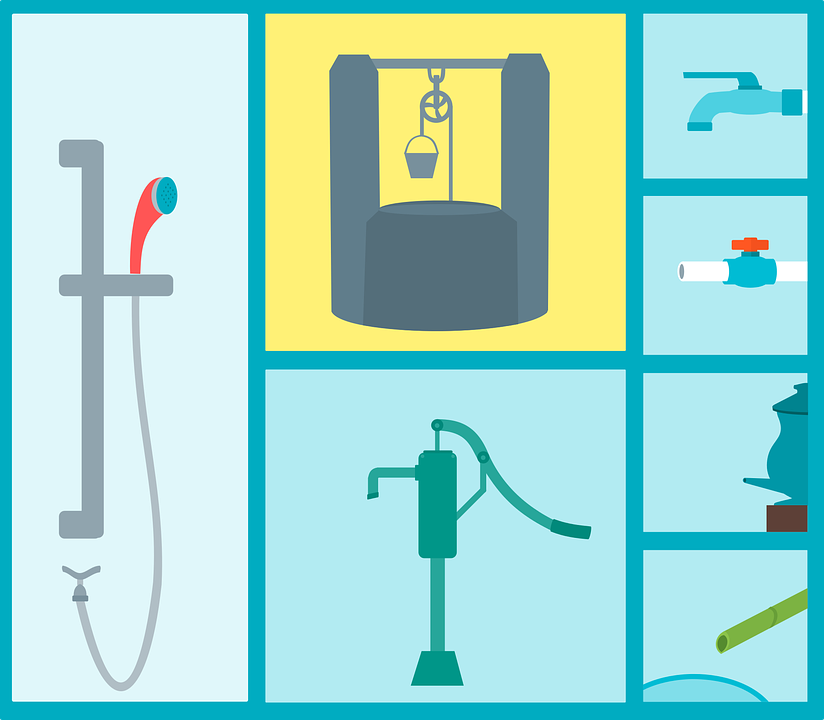

Choose Efficient Pump Type

The average pump efficiency is below forty percent. Over sizing comes in the design phase as the practice for adding multiple safety elements is common. It requires both the engineer and the pump manufacturer to work close cooperation in choosing the right water pump engine. On top of size, they must look at the power needs, speed, and drive type.

Proper Pump Size

Proper sizing of the pump reduces energy consumption. Remember that centrifugation pumps consumer up to sixty percent of motor energy and carries the highest process equipment maintenance cost. You can consider diesel water pumps to save on energy cost and consumption. Engineers add many safety elements in the designing phase making the pump oversized which only skyrockets the maintenance and energy cost. You can ask around for small diesel engines for sale and chose one that fits your interest.

Using Multiple Pumps

You will save more energy when you allow multiple pumps to run as part of a parallel pumping system. Such systems work well when each pump run independently and not at the same time. Operating multiple pumps concurrently is okay as stipulated by the flow requirements that are unique to the application in use. From this, you can begin to appreciate the advantages of power supply that run efficiently.

Eliminating Unnecessary Uses

Many people overlook the impact of reducing unnecessary energy consumption. Pumping facility efficiency measures involve using pressure switches, closing down pumps that are not in use, or even using diesel water pumps. All pumping units are unique; meaning more opportunities to save energy. Again, to help you accomplish this consider choosing from the many small diesel engines for sale.

When you install a proper power supply, it will keep your system safe even where you suffer a blackout. Nonetheless, everything begins by hiring an experienced professional with an understanding of how water pump works.